“Can I 3D print sex toys?”

With today’s technology, why not? Anything is possible! But if you do decide to make one of your own, you may want to manage your expectations.

There are a lot of great ways to use 3D printing for sex and kink. But there are also plenty of bad ways. And that’s what we’re here for. We’ll help you understand how 3D printing works and the dangers it could pose to your health. We’ll also teach you a super quick, easy, and safe alternative way to make sex toys using a 3D printer.

3D Printed Sex Toy: Body Safety Concerns

NSFW 3D prints were such a novel idea a few years ago and many start-up companies jumped on the bandwagon. 3D printers are great for making toys that stay outside the body, such as floggers and paddles. But insertables? Not so much.

For starters, the surface of the finished products is super rough. Plus, the layer-by-layer printing process leaves porosity in the printed toy. These microscopic gaps are impossible to clean, making them the perfect breeding ground for bacteria.

There are workarounds you can do if you really want to print your toy directly from the 3D printer. First, you can hand sand the toy until the surface is as smooth as possible. Next, spray it with a silicone spray. Let it dry for 20 minutes. Repeat the coating process 3-4 times. Once the final coat dries, it’s ready for use. But even then, we still doubt the durability of the finished product. Call us overcautious, but it’s always better to be safe than sorry.

Other options include creating a mold where you can cast your toy using silicone and sending an STL file of your design to a 3D printing service provider. New materials and more accurate 3D printers are being developed as we write this. But of course, new technology takes time before it reaches the masses. So until then, these are your only options.

How to 3D-Print Dildo Sex Toys

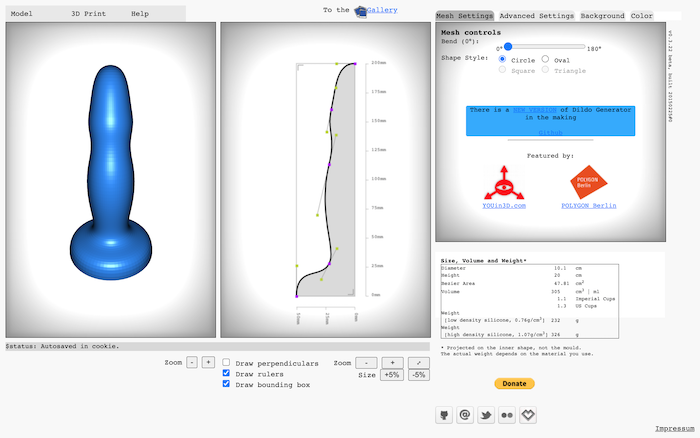

3D-printing a dildo is surprisingly easier than you may think. All you need to do is prepare the printer and materials, design a toy using an online sex toy generator like dildo-generator.com, print, and wait. But as we’ve mentioned, sex toys printed straight from the 3D printer are highly porous, making them unsuitable for insertion.

A safer option is to 3D-print dildo molds instead of the dildos themselves. While silicone 3D printing is now possible, it’ll take you hours just to print one dildo. So it’s more practical to create a mold you can reuse if you want to make more than one sex toy. It’s also great for creating custom one-offs.

If you’ve never casted or done organic digital sculpting before, this is the perfect beginner project for creating your own sex toys. The whole process will take some time to complete. We suggest allotting a whole day for it, with a friend or bed-fellow to make the experience more fun.

But before we start, let’s take a look at what you’ll need.

- A 3D printer and filament. It doesn’t matter what type of filament you get as long as it doesn’t warp, such as Nylon, ABS, or polycarbonate (PC). We found Polylactic Acid (PLA) and Polyethylene Terephthalate (PETG) to work best for this project.

- Epoxy resin. For coating the mold.

- Body-safe silicone. Platinum cured silicone is a better option than the tin cured one. It’s more expensive, but it’s more stable. The curing process also doesn’t produce harmful byproducts. There are tons of options out there but we personally like the Barnes Platsil Gel-10. It has the right balance of hardness and softness. But that’s just us. You’re free to experiment and discover things on your own.

- Disposable cups and chopsticks. For mixing the silicone.

- Cable ties (zip ties). For holding the molds together.

- Small brushes. Makeup brushes will do.

Optional materials:

- Silicone colorant. Adding a pigment will make your toy look more interesting and unique.

- Silicone mold release spray. This isn’t necessary but will definitely make it easier to remove the mold after the casting.

- Vacuum degassing setup. This is mostly for aesthetic purposes as it’ll help remove the tiny bubbles in your finished product. These bubbles have no effect on the overall texture or durability of the toy. When selecting a degassing set, make sure the pot is big enough for the mold. It doesn’t matter what pump you get as long as it can get to full vacuum or -1 bar.

Step 1: Prepare the Printer and Materials

Setting up the 3D printer is the most technical step you’ll do in this whole process—and even that is surprisingly easy. You don’t need to memorize all the technical terms. Just follow the manual to know which goes where. When everything’s pieced and aligned together, it’s ready to go. All you have to do now is feed it your design.

Of course, some printers may be harder to figure out than others. If you find yourself stuck, you can check how-to videos on YouTube or you can call your printer’s customer service for assistance.

Buy the materials you need to print the mold, such as the filaments and body-safe silicone. We suggest you get more than you need, especially if it’s your first time casting your own toy. If you’re not sure what to get, don’t hesitate to ask the silicone shop owner for guidance. Explain your goals with as much detail as you can without overstepping someone’s boundaries.

If you want to add color to your toy, powdered pigments typically work best in silicone. But some additives, such as sulphur, can inhibit the silicone curing process. So make sure to ask the experts at the shop for input.

Step 2: Design a Dick

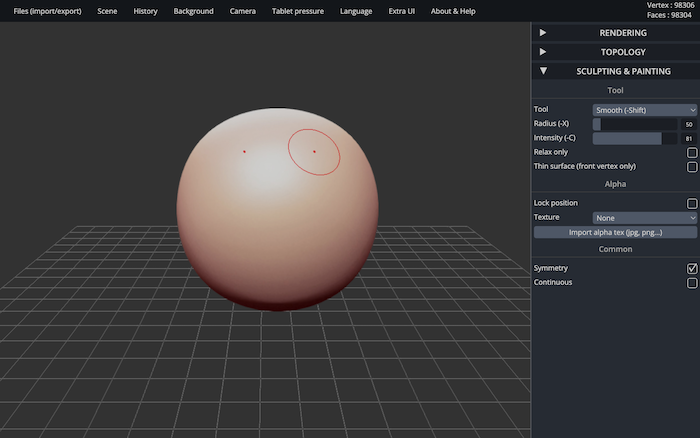

3D printing isn’t magic—although it looks like it! It won’t print anything without inputs from you, so you need to carefully design what you want to cast. Fortunately, websites like dildo-generator.com and SculptGL make 3D modelling a breeze. You can also scan an object if you have a 3D scanner lying around.

You can also use Fusion 360 or TinkerCard if you want more symmetrical sex toy shapes. For more organic designs, you can try organic/soft modeling. When designing your dildo, keep in mind that little crevasses can become a breeding ground for bacteria. So avoid making anything too detailed.

Step 3: Turn Your Design into a Mold

You can use 3D Builder if you’re on Windows, or Fusion 360 if not, to turn your model into a mold. To start, make sure to cut the toy out of a bigger shape like a cylinder, and then cut it in half to create two sides.

The next step is to add registration nobs to help align the mold. You can create any shape you want for the nobs as long as both halves firmly stick together when you close them. Also, make sure the holes are slightly bigger than the pegs by about 0.3mm on each side.

You can also download a ready-made dildo mold model STL file if you don’t want to go through all the trouble of designing your own mold. Once you already have your desired dildo mold design, all that’s left to do is print. Now, this part will take a while.

Step 4: Smooth with Wax

Mix the epoxy on a disposable cup as per instruction. You won’t need much. Brush a thin layer of epoxy onto the inside parts of the mold to cover up the layer lines from 3D printing to prevent them from transferring to the final product. If you skip this part and they do transfer, your sex toy will have bacteria traps that are impossible to clean.

Let the epoxy cure for about 8-12 hours at room temperature. You can put the mold in the oven to speed up the curing process, but be careful not to melt the plastic, especially if you’re using PLA material.

Once it’s cured, spray both sides of the mold with a good amount of the release agent to make it easier to remove the mold later on. Next, tie the two sides together with cable ties as tightly as you can.

Step 5: Cast Your Toy

Now you’re ready to cast your sex toy.

Measure two parts of silicone into two disposable cups by volume or by weight depending on the product you’re using. When measuring, take into account the bits that’ll get stuck in the cups.

Mix your colorant into the first cup before mixing it together with the silicone from the second cup. The order is important. You can’t add any more pigment once both cups of silicone have been mixed together. Stir slowly in one direction to minimize the formation of bubbles.

Using a vacuum and pressure pot will remove bubbles, but it’s not necessary. Internal bubbles are harmless. It’s the surface ones that aren’t okay because they can trap moisture and grow bacteria. You can check out YouTube for a step-by-step guide on degassing.

Pour both cups into a third one to ensure you get equal amounts of the silicone from each cup. Mix thoroughly before pouring it into the mold. Your clock starts now. Your working time depends on the product and amount of silicone you’re using. Make sure to complete all steps and pour the silicone into the mold with plenty of time to spare.

Tap the mold on a hard surface or pop it back in the degassing vacuum chamber to remove the bubbles. Set it aside and wait for the silicone to cure. Curing time depends on the product you’re using. Once it’s cured, pry the mold open with a flat head screw. Remove the finished product and trim off extra bits.

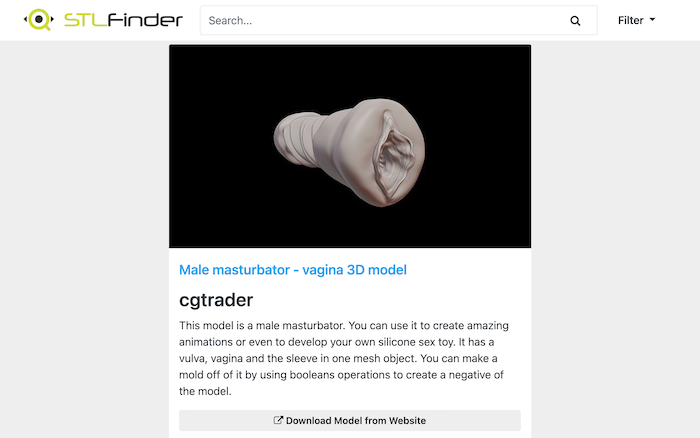

3D Printed Fleshlight Toys: The New Frontier of NSFW 3D Printing

Silicone is one of the best materials used for adult toys. And why not? Aside from being hypoallergenic and non-comedogenic, it can also withstand extreme temperatures. But what makes it such a great material is also what makes it not viable for 3D printing.

Because of its high heat resistance, it’s not possible to melt and print it layer-by-layer like how regular 3D printers work. Many companies have tried to simulate silicone using other elastic 3D printing materials but were never really successful. None can match silicone’s durability and flexibility.

Fortunately, new developments in the 3D printing world have made it possible to print toys based on lady parts, such as a 3D printed pocket pussy. Hurray for technology!

Keep in mind that silicone 3D printers are still in its infancy and they’re not yet widely available to the general public. Silicone filaments and resins are also not sold commercially yet. The ones you can find online are mostly likely fake, so be extra vigilant.

There are companies that offer silicone 3D printing services, so you can still turn your designs to life. All you have to do is submit the OBJ or STL file of the object you want to print to the service provider and they’ll do the rest. Just make sure to ask if they 3D-print adult toys first before uploading your 3D model.

One last thing. Most 3D printing machines have very small build volumes and slow print speeds, which severely limits production capabilities. So you won’t be able to get large volumes of the object you want printed. If you plan to 3D-print sex toys at a large scale, we suggest you use the injection mold method instead.

Final Thoughts

Sex toy 3D printing may not be perfect but it’s still a fun way to explore new dimensions of your creativity. You can create custom one-offs or even go avant-garde. You can let your imagination run wild instead of being stuck with the ones that already exist in the world.

3D printing technology has come a long way. But there’s still more to be achieved. It’d be interesting to see how this technology develops in the coming years as new materials and more precise printers emerge.